Quick Highlights:

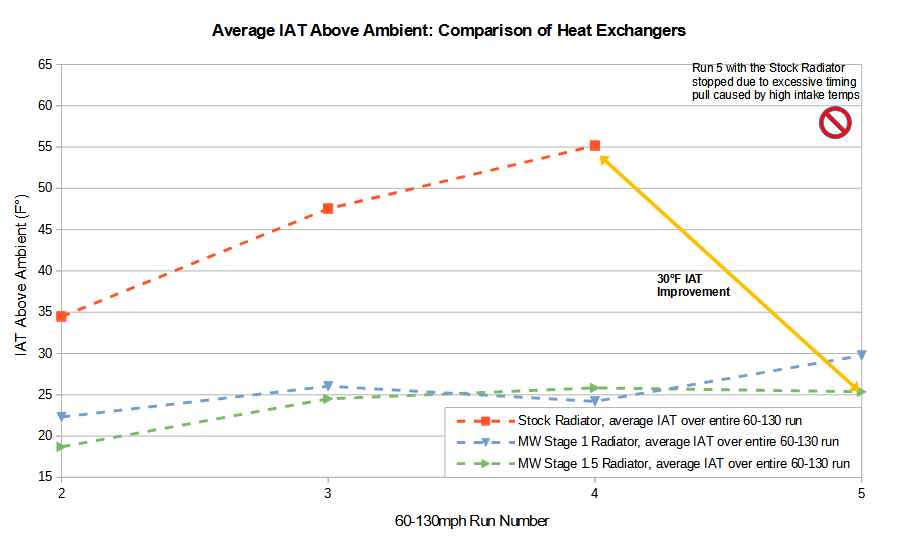

1. Stock system has very poor heat soak characteristics. Intake Air Temps (IATs) rise about 15% per 60-130mph run in 90°F ambient conditions, resulting in major power loss after a few pulls.

2. Our Stage 1 system reduces IATs by 45% and 25°F after 5 successive pulls. One of the biggest benefits is reduced heat soak capacity and the ability to keep putting down more power. We achieve this through a proprietary core design and changing the system from a single pass to a triple pass coolant path.

3. Stage 1.5 further enhances Stage 1 with the additional auxiliary cooler which provides 54% and 30°F peak IAT reduction at the 5th run.

4. Our Aux cooler can double as an engine cooler and shows up to 12°F cooler engine coolant temperatures (ECT) after 5 pulls.

5. Made in the USA.

Stage 1: Main Intercooler Radiator

Stage 1.5: 2 piece kit, Main + Auxiliary Intercooler Radiators

Stage 2: 3 Piece kit, Main + Auxiliary Intercooler Radiators plus an Auxiliary Engine Radiator

Vehicle Fitment:

- 2016-2022 Mercedes-Benz C63 AMG

- 2015-2022 Mercedes-Benz C63 AMG S

- 2017-2022 Mercedes-Benz AMG GT

- 2018-2022 Mercedes-Benz AMG GT C

- 2018-2022 Mercedes-Benz AMG GT R

- 2016-2022 Mercedes-Benz AMG GT S

- 2018-2022 Mercedes-Benz GLC 63 AMG

- 2018-2022 Mercedes-Benz GLC 63 AMG S

Installation Notes:

This product requires vacuum filling per the official Mercedes work instructions and should be carried out by a reputable mechanic with the proper tools. Failure to properly install will lead to inferior results.

Detailed Write-up:

On our C63’s, we have 3 front facing radiators that serve multiple purposes. The primary center and LHS (driver’s side in the USA) work together to cool the intake charge temperatures and well as the transmission simultaneously. As your transmission warms up, it directly affects your intake air temperatures which isn’t ideal.

To combat this rise in temperature, we have custom designed from the ground up a single and dual radiator option. We explored multiple avenues, performed multiple iterations of testing, and came up with a solution that is proven to reduce undesirable temperatures. We partnered with one of the best radiator core companies in the world to optimize heat rejection which translate to lower intake temps and a happier transmission.

Test Method:

We went through multiple rounds of testing with over 5 different concepts to arrive at the product shown below. We varied core thickness, fin and tube sizing, water routing and end tank design to arrive at our final configuration shown below.

Our final testing was done in the Texas summer heat (90-95F°) at close to 4000DA with our hybrid turbo setup running 27+PSI of boost. This combination of high ambient temps with high boost greatly stresses the components the intercooler system is trying to cool. Each test was done with successive rolling pulls, with approximately 60 seconds of time between each run. This causes the entire system to heat soak and progressively get hotter after each pull. Additionally, all of the data shown below starts at Run 2. We did this to normalize the results and pre-stress the system equally between each configuration to rule out variances due to starting temperatures and transmission warm-up. At the beginning of each set of tests, the first run was excluded as all systems were more or less “cold” and we do not believe the results are valid.

Stock Baseline:

With the completely stock system, we tracked IATs pull after pull and created the following charts. We measured average intake temperature and peak intake temperature per 60-130mph run to obtain a holistic picture of how the stock system performs. As shown below, the system raises 8-14°F per run, and by the 4th run the car was running poorly with massive timing pulls due to high intake temperatures. We planned to do 5 pulls but the power loss was so bad we could not manage to do 5 back to back pulls without excessive timing pulls and had to cut the test short.

Stage 1 Results:

This option replaces the primary radiator with our Stage 1 model. It shows significant intake temperature reductions and greatly improved heat soak mitigation. To achieve our results we partnered with PWR to custom design our core which uses a proprietary fin arrangement, fin density and coolant tube design. In addition to the core design we also rerouted the entry coolant passage and converted this system from a single pass to a triple pass design. With these enhancements, we were able to reduce IATs by 45% and 25°F after 5 successive pulls. One of the biggest benefits is reduced heat soak capacity and the ability to keep putting down more power without pulling timing like the stock system.

Stage 1.5 Results:

This option uses our main core plus the additional auxiliary cooler on the left hand side. Our new design is larger with another proprietary core design that further enables our great results. The main and auxiliary cooler were able to achieve peak IAT reductions of 54% and 30°F at the 5th run.

Stage 2 Results:

We designed our auxiliary coolers to be reversible and to be able to mount to either side of the vehicle. On the right hand side the auxiliary cooler acts as an additional engine radiator. We are pleased to report that the upgrade of this cooler consistently reduced engine coolant temps by 9-12°F pull after pull, resulting in a happier engine.